Operations

2021 CAPITAL EXPENDITURE

RETURN ON CAPITAL EMPLOYED

CApital expenditure

Millions of Euros

Umicore believes in proximity to our customers and in working closely with our customers’ teams as a true industrial partner.

As a local partner, we can reduce emissions from the supply chain while offering the best possible tailor-made products and services. Proximity to our customers also allows us to optimize continuity of operations. Our decentralized approach facilitates local operations, as business units and sites have operational flexibility and can respond quickly to the dynamics in local markets, both in the upstream supply chain and in the downstream needs expressed by customers.

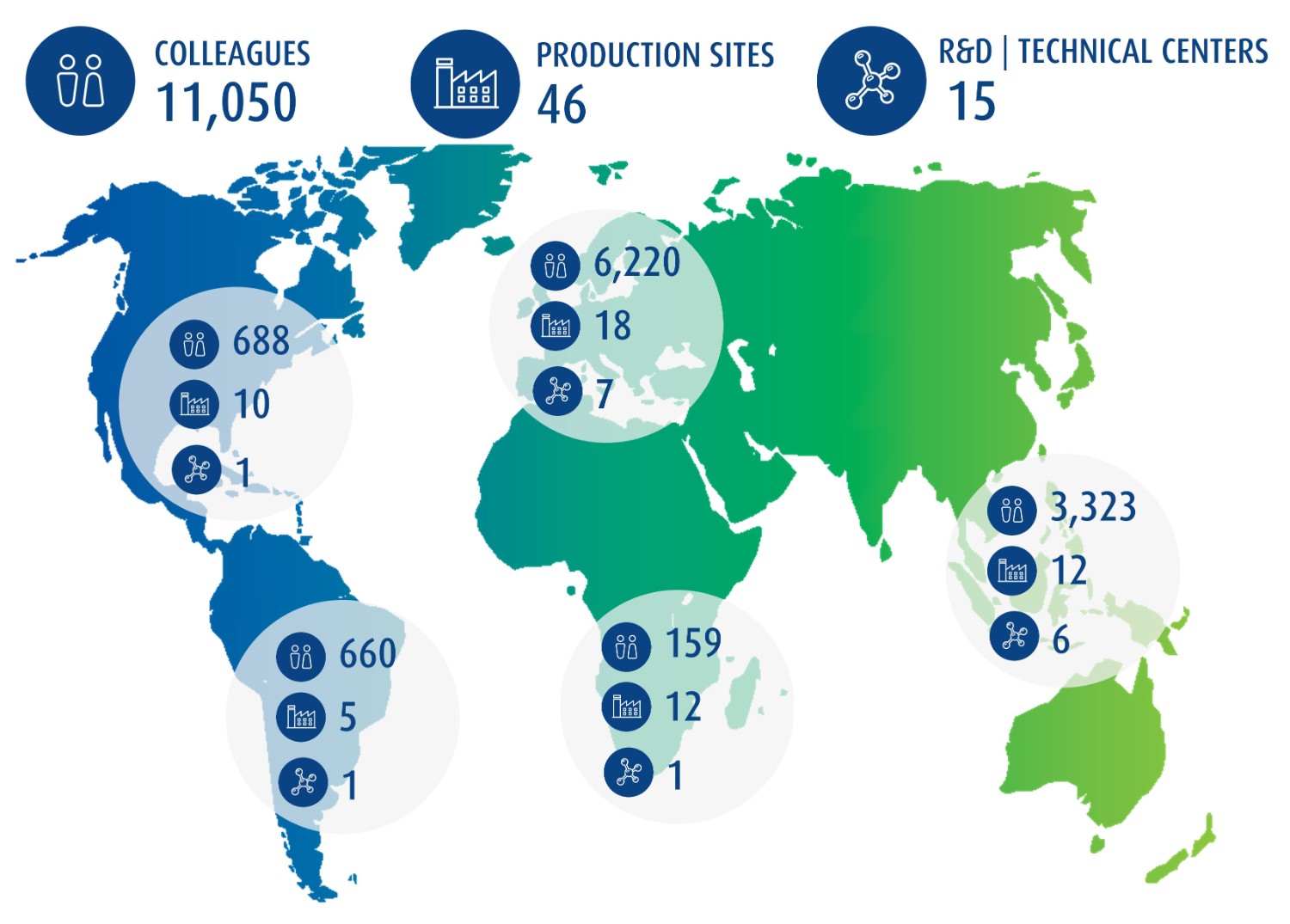

Umicore is a global company creating products and services for a broad range of customers located in 101 countries and supplied from a diverse supplier base in 87 countries. To cater to its international customer base, Umicore is present in growing and established markets in Asia, Europe, North America, South Africa and South America.

With headquarters in Brussels, Belgium, we work from 46 production sites, 15 R&D sites and 33 other sites, including sales and marketing offices. Many sites accommodate a combination of business units, corporate or other activities.

One of our newest multiple activity sites is the Americana site in Brazil, which we see as a blueprint for future industrial sites. Ecological design means the site primarily uses renewable energy, while optimizing energy and resource utilization. Americana was also purpose-built with open spaces to stimulate dialog among the various activities present on the site.

Umicore’s Catalysis business group contains our Automotive Catalysts, Fuel Cells & Stationary Catalysts and Precious Metals Chemistry business units. Their activities focus on the development and production of catalyst formulations and systems used to abate harmful emissions from combustion engines, for use in fuel cells and chemical and life science applications. These catalysts use mainly Platinum Group Metal (PGM) chemistries, in which Umicore has over 50 years of experience.

Umicore Automotive Catalysts is one of the world's leading producers of catalysts used in automotive emission systems for light-duty and heavy-duty vehicles. Its catalysts are used in a wide range of powertrains, including gasoline and diesel engines, natural gas, and alternative fuels, and are increasingly important in engines supporting mild and full hybrid vehicles. The business unit develops and manufactures three-way catalysts (TWC) and particulate filters (cGPF) for gasoline engines as well as diesel oxidation catalysts (DOC), particulate filters (DPF), NOx (Nitrogen oxides) and SCR (selective catalytic reduction) systems for diesel engines. In addition, it produces catalysts for heavy duty diesel (HDD) vehicles such as buses and trucks and for motorcycle or small engine applications.

Umicore Automotive Catalysts’ worldwide operations deliver products to automobile manufacturers in Asia (with sales offices in India, Thailand, Japan and China), Europe (offices in Denmark, Germany, Luxembourg and Italy) and North and South America (USA and Brazil). Activities are driven by the worldwide efforts towards stricter emission standards for all type of combustion engines and hybrids.

Through our Fuel Cells & Stationary Catalysts business unit, Umicore supports future growth in both Proton Exchange Membrane (PEM) fuel cells and stationary catalysis, targeting a broad range of industries including manufacturing, hydrogen production, power and propulsion and the automotive industry. It aims to support its customers in developing clean engines and reaching zero emission mobility and power supply. The business unit benefits from Umicore’s established worldwide presence in both business areas and in 2021 added a strong footprint in China, locating its headquarters in Shanghai. Fuel cell drivetrain technology is currently benefiting from a first uptake as an environmentally friendly alternative to internal combustion engines. In 2019, the business unit commissioned a mass fuel cell catalyst production plant in Korea to meet the growing demand of its customers.

Umicore Precious Metals Chemistry develops and manufactures metal-based catalysts, active pharmaceutical ingredients (APIs) and chemical vapor deposition (CVD) precursors. Its expertise includes the conversion of metals into inorganic and organometallic chemicals, APIs and homogeneous catalysts as well as the handling and manufacturing of highly toxic or sensitive materials. Its key end-markets are automotive, chemicals, electronics and pharmaceuticals.

In 2021, the vast majority of the energy supply for our catalyst production in Europe (Karlskoga, Bad Säckingen), South America (Americana) and North America (Burlington) was from renewable energy sources, helping our customers meet their sustainability objectives.

Umicore’s Energy & Surface Technologies (E&ST) business group contains our Cobalt & Specialty Materials, Rechargeable Battery Materials, Metal Deposition Solutions and Electro-Optic Materials business units. The business group aims to power the future. Our innovative materials enable the transition to electromobility and are also used in applications including portable electronics, energy storage and power tools. One in five lithium-ion batteries ever produced contains Umicore technology. We offer Cobalt & Specialty Materials as well as Rechargeable Battery Materials for rechargeable lithium-ion batteries and we supply products for metal-based electroplating and PVD coating from our Metal Deposition Solutions business unit and material solutions for the space, optics and electronics sectors from our Electro-Optic Materials business unit. Our operations for E&ST are mainly in Asia and Europe and we sell our products to customers worldwide. The business group’s products are largely based on cobalt, nickel and germanium.

Umicore Rechargeable Battery Materials is a leading supplier of active cathode materials for lithium-ion batteries. These batteries are the main battery technology for the new generation of hybrid and full electric vehicles and are used in a large portion of today’s portable electronic equipment. Over recent years Umicore has been expanding capacity for its cathode materials to cater for growing customer demand, in particular from the electric vehicle segment. Today Umicore is supplying its customers from its sites in China and Korea and soon we will start production from our greenfield plant in Nysa, Poland, the first industrial scale cathode materials plant in Europe, making Umicore the only cathode player to produce industrial cathode materials on two continents and to supply cathode materials to global customers with identical quality and performance from different plants across different regions.

Umicore is currently serving the European EV market out of its Korean plant awaiting the start of commercial production at the plant in Poland. The new plant was successfully commissioned in 2021 and the qualification of its flexible production lines, with high- and mid-nickel capabilities, is ongoing with production expected to start mid-2022. Based on the growing demand from customers in Europe, Umicore is further expanding the Nysa plant with additional production lines, which are set to come on stream by the end of 2023, as previously announced. On finalization of this expansion, the Nysa plant will have a total production capacity of 20 GWh. The Nysa site can accommodate a potential capacity of more than 200 GWh, and we currently plan around 40 GWh at the end of 2024 as an interim step.

The manufacturing process in Nysa reflects the latest developments in Umicore’s proprietary cathode materials production system and process. This Gigafactory will be industry-leading in terms of purity, quality and consistency, and represents a very important asset for Umicore. Nysa will be supplied with 100% green electricity from the start of production, adding a sustainability dimension in favor of our product offer.

The business unit Cobalt & Specialty Materials is a worldwide leader in the recycling and refining of nickel and the transformation and marketing of cobalt and nickel specialty chemicals. Its broad expertise covers a multitude of applications in both chemical and powder metallurgy. The unit covers all steps of the value chain, from sourcing to distribution, with production units and sales offices on all continents.

Umicore’s Metal Deposition Solutions business unit is one of the world's leading suppliers of products for precious metal-based coating of surfaces in the nano and micrometer range. The unit masters the two highest-quality coating processes: electroplating and PVD coating which offer customers tailor-made coating processes for their specific needs. Its coating solutions are used by manufacturers in the electronics, semi-conductor, automotive, optics and jewelry industries.

The Electro-Optic Materials business unit supplies germanium-based material solutions to customers around the world. Its main markets are thermal imaging and opto-electronic applications, for which it supplies germanium wafers, infrared lenses and optics, and germanium-based chemicals.

In our Recycling business group we give new life to used metals. The business group recovers a large number of precious and other metals from a wide range of waste streams and industrial residues. Its operations also extend to the production of jewelry materials (including recycling services). This segment also offers products for various applications including chemical, electric, electronic, automotive and special glass applications. It consists of three business units, with at the center its flagship Precious Metals Refining plant in Hoboken, Belgium, unique in its kind.

Umicore Precious Metals Refining operates as one of the world's largest precious metals recycling facilities and is the world market leader in recycling complex waste streams containing precious and other non-ferrous metals, serving customers worldwide. In 2021, the Hoboken plant benefited from previously implemented innovations and debottlenecking investments in its PGM refinery and achieved record earnings and revenues. The recent innovations allowed Umicore to maximize input of highly complex PGM materials, such as spent automotive and industrial catalysts. The regular maintenance shutdown in the second half of the year was completed as scheduled and operations restarted smoothly. As described in title story, the production plant in Hoboken is continuously investing to minimize its environmental impact.

Umicore Precious Metals Management is a global leader for the supply and handling of all precious metals. The business unit acts as a link between the recycling activities and producers in need of precious metals (internal as well as external). We guarantee supply continuity through sustainable sourcing of raw materials.

The Jewelry & Industrial Metals business unit supplies precious metal based products to jewelers and precious metals processors as well as semi-finished products and alloys for industrial soldering products and tradable precious metals. It also offers its precious metal recycling services to its clients for their jewelry and production scrap. In addition to the highly sophisticated precious metals recycling facility in Hoboken, Belgium, we have precious metals recycling operations in Australia, Austria, the Netherlands, Brazil, France, Canada, USA, Germany, Japan, Thailand and the UK. Our products and services are marketed in all these regions.

In 2021 Umicore was proud to establish its newest business unit, Battery Recycling Solutions (BRS). Battery recycling is an essential part of our contribution to the sustainable electrification of the automotive industry as it enables us to close the loop in battery manufacturing. More details of the creation of this business unit can be found in the section Innovation. Please also see see the ACC press release.

In 2021, capital expenditure totaled € 389 million, compared with € 403 million the previous year, with € 166 million spent in the first half.

Energy & Surface Technologies accounted for close to 60 % of Group capital expenditure, driven by European expansion investments for Rechargeable Battery Materials. This resulted in a temporary slow-down in the capital expenditure of Energy & Surface Technologies compared to 2020 and is expected to result in some spill-over of capital expenditure into 2022.

In Catalysis and Recycling, capital expenditure only slightly increased compared to the low spending levels of 2020. In Catalysis, Automotive Catalysts continued to focus on investments to optimize production footprint and targeted capacity expansions. In Recycling, the increase in capital expenditure was earmarked for environmental and safety-related investments in Precious Metals Refining.

Capitalized development expenses amounted to € 28 million, slightly down compared with 2020. Umicore’s accelerated growth investments in Rechargeable Battery Materials - including the spill-over effect mentioned above - are expected to result in higher Group capital expenditure in 2022 compared with the previous year.

Umicore has investments in various business activities over which it does not exercise full management control. Associate companies are those where Umicore has significant influence over financial and operating policies, but no control. Typically, this is evidenced by ownership of between 20% and 50% of the voting rights, while joint ventures usually entail a 50:50 split in ownership and control. Joining forces is a way to speed up technological developments, gain access to specific markets, or share investments.

Where management control is not exercised by Umicore, we are able to guide and control the management and monitor business developments through representation on the board of directors. Although we cannot impose our own policies and procedures on any associate or on any joint venture where we do not possess majority voting rights, our expectations that the operations be run in accordance with the principles of the Umicore Way are clearly communicated.

Umicore is rigorous in safeguarding any intellectual property that is shared with associate or joint venture partners. For a full list of associate and joint venture companies, see note F17.

Umicore and Volkswagen AG to create European EV battery materials Joint Venture

Umicore and Volkswagen AG announced in December 2021 their intention to create a joint venture for the production of precursor and cathode materials in Europe to supply Volkswagen AG’s European battery cell production. It is anticipated that this partnership, the first of its kind in Europe, will start with an initial annual production of 20 GWh in 2025 for supply to Volkswagen AG’s plant in Salzgitter, Germany, with the ambition to grow to an annual production capacity of up to 160 GWh by the end of the decade.

The partnership will provide Umicore with secured access to a significant part of the European demand for EV cathode materials while providing Volkswagen AG access to Umicore’s advanced precursor and cathode materials, proven production capabilities and upstream expertise. The partnership is expected to unlock significant economies of scale and will allow investment requirements to be shared between the partners while protecting critical IP and know-how for Umicore.

In the context of the joint venture, Umicore and Volkswagen AG will also collaborate on the sustainable and responsible sourcing of raw materials, which is a strong area of expertise at Umicore. At a later stage, both parties aim to include battery recycling and elements of refining in the scope of the JV. The planned JV is subject to final agreements and customary conditions, including regulatory approvals.

Volkswagen AG has chosen Umicore as a partner not only because the two companies share the same sustainability ambitions, but also because Volkswagen sees Umicore as a leading player in this industry, uniquely combining state-of-the-art product and process technologies with a proven and well-established track record in mass scaling at highest quality levels, and strong capabilities in the ethical supply of raw materials.

For more, please see the Umicore and Volkswagen JV announcement.

Belgium

Belgium Germany

Germany Worldwide

Worldwide