Our business

Our purpose at Umicore is to help the world transition to cleaner mobility by providing hi-tech materials, including emission control and fuel cell catalysts and a wide spectrum of rechargeable battery materials, and by closing the materials loop.

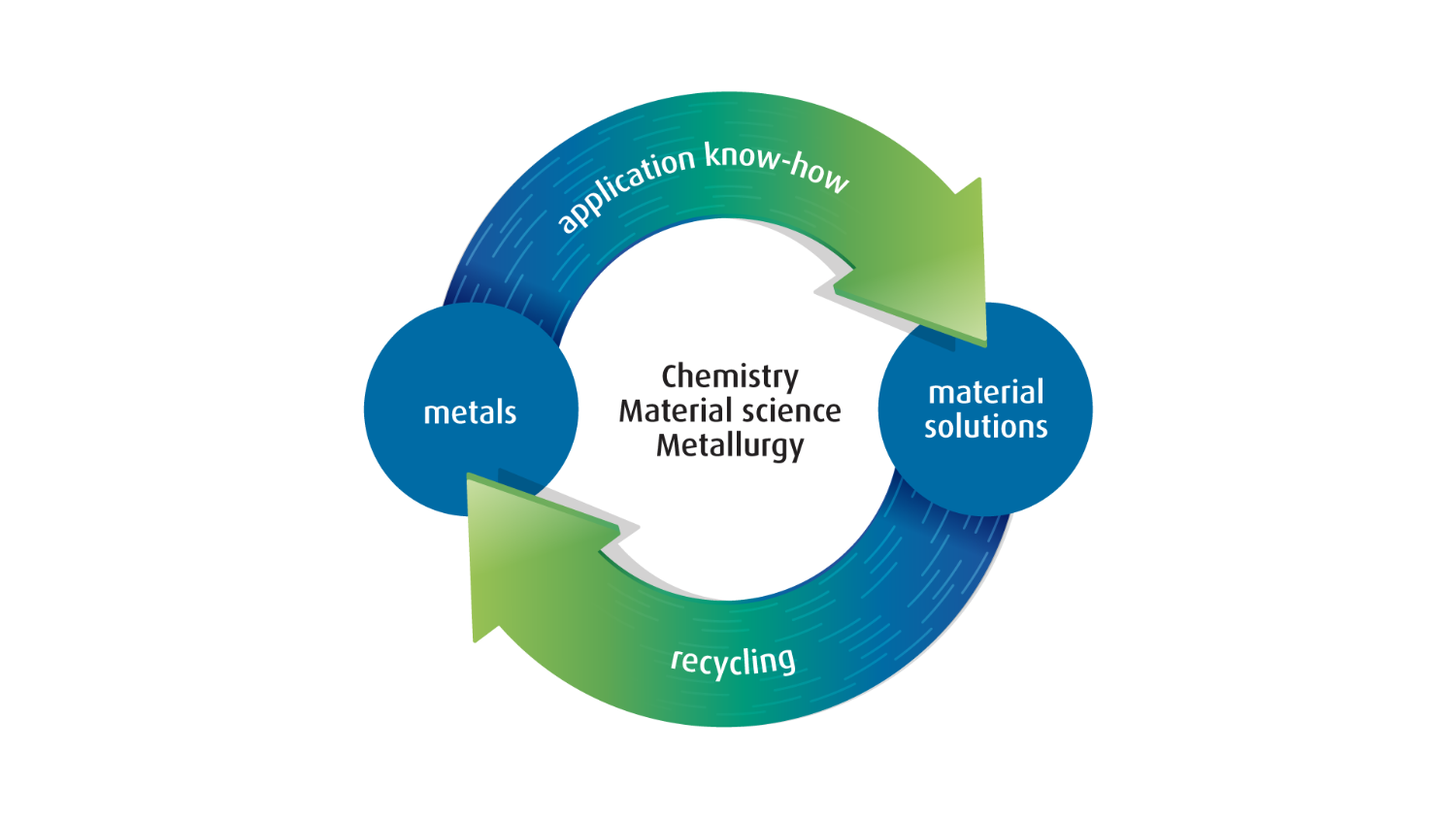

Our mission is to provide clean mobility solutions for all automotive platform types and to recycle these materials when they reach the end of their useful life. Using our metallurgy, chemistry and materials science expertise and know-how, our closed-loop business model is a powerful differentiator and the basis for our business and our long-term strategy.

Our work in clean mobility is multifaceted. We develop automotive catalysts to clean the exhaust gases from internal combustion engines for light-duty and heavy-duty vehicles of all fuel types. We also develop the rechargeable battery materials that power hybrid, plug-in hybrid and full electric vehicles. Additionally, we produce high-performance catalysts for vehicles powered by fuel cells.

At the same time, Umicore is one of the world’s most sophisticated recyclers of precious and other valuable metals. Our state-of-the-art facilities can recover 28 precious and non-ferrous metals from sources including industrial residues, used electronic scrap, batteries, automotive and industrial catalysts, fuel cells.

As a leader in automotive catalysts and a pioneer in EV battery materials, we aim to stay ahead of the curve. Our innovation strategy couples Umicore’s extensive internal expertise with a collaborative network of universities and start-ups, allowing us to respond quickly to fast-moving trends in clean mobility and recycling. More about how we innovate to develop tailor-made technology for our customers can be read in Innovation.

Reducing air pollution is key to achieving global climate targets and supported by increasingly stringent automotive emission legislation and public advocacy for clean air regulation. In Europe and Asia, legislators are developing clean mobility policies to further reduce SOx, NOx and other harmful emissions and are strengthening emission standards to encourage the design of ever-more innovative emission control systems.

The transport sector is the fastest growing source of global greenhouse gases, with the largest share from road transport. Electrified transport is essential to deliver on targets for low carbon mobility by combining energy-efficient systems with renewable energy sources. Incentives favoring electric vehicles are increasing globally.

Developing new technologies such as increasingly high performance automotive catalyst technologies and powerful rechargeable batteries intensifies the demand for a wide range of metals. However, mining metals such as lithium, nickel and cobalt from primary sources has significant environmental impacts, including a high carbon footprint and disruption to nature and local communities. Easy-to-mine deposits are increasingly scarce and ore bodies contain fewer valuable minerals. Umicore’s recycling services are a solution to help mitigate this challenging trend of resource scarcity.

The green economy is rapidly expanding to meet the urgent demands of climate change. Umicore’s clean mobility materials and recycling services are key contributions to a sustainability-driven world, and we have clear targets for progress over the coming years.

Umicore’s approach to achieving clean mobility is two-pronged. Our work in battery materials and recycling supports the global shift to electromobility, while in the short- to mid- term, we continue to focus on catalysis technologies to improve air quality.

Catalysts

The road to achieving clean modes of transport begins with catalytic converters, which reduce the emissions of harmful pollutants from internal combustion engines. Our advanced precious metal solutions are vital, providing highly efficient catalysts to remove harmful gases such as nitrogen oxides (NOx). As clean air legislation becomes ever more stringent at a time when internal combustion engines are still predominant, Umicore can help ensure that the final years of fossil fuel transportation are less damaging to the environment.

Batteries

Electric vehicles are increasingly part of our daily lives. Umicore provides state-of-the art battery materials to power electric vehicles, in collaboration with key players in the market. The automotive industry is facing huge challenges, including competitive cost/performance ratios, fast charging times and the highest safety standards. Today, Umicore offers its customers the best product portfolio to meet these needs. Our key offering is a wide portfolio of active cathode materials, the single most valuable component of rechargeable lithium-ion batteries, providing longer driving ranges and better performance to electric vehicles. While the battery pack represents approximately 30% of the electric car’s value, the active cathode material is worth approximately 30% of the pack’s value, meaning Umicore provides around 10% of the overall value to electric vehicles. This significant percentage bears witness to our pioneering role in furthering electro-mobility.

Fuel Cells

Umicore has 30 years’ experience of manufacturing fuel-cell catalysts for hydrogen vehicles. We have proven know-how in developing catalysts and scaling up to industrial-scale production, as demonstrated by Umicore solutions that have been on the road for many years. Fuel cell-powered vehicles combine the advantages of long driving ranges, short refueling times and zero emissions, making fuel cell-powered automotive particularly attractive for long-distance or high energy haulage applications.

Developing clean mobility solutions is only the first step. At Umicore, we understand that the positive environmental impact of our innovations would be diminished if the spent materials were eventually discarded. For this reason, more than two decades ago we created our unique closed-loop business model, in which we recover the metals and reintroduce them into the production cycle to produce new materials.

Metals are an outstanding ingredient for sustainable materials production because they can be recycled infinitely without losing any of their chemical or physical properties. This allows us to use metals produced from recycled sources, such as production scrap, residues from customers, other industries and our own operations, as well as post-consumer materials.

We have the expertise and know-how to determine and extract the platinum, palladium and rhodium content in end-of-life catalytic converters from internal combustion engines. Once recycled, these metals can be used to produce new catalytic converters for next generation vehicles, thus closing the materials loop. More than half of our metal needs have been covered in this way, consistently over the past several years.

Similarly, we have capitalized on our long track record in battery recycling to be an early entrant in the EV battery recycling market. Sourcing the accelerating surge for battery materials will be a sizeable challenge across the entire value chain and we are confident that our long-standing experience in recycling will be of benefit.

We purchase the remainder of our metal needs from sustainably and ethically vetted primary sources, under the conditions defined in Umicore’s Global Sustainable Sourcing Policy, Umicore’s Sustainable Procurement Framework for Cobalt and Umicore’s guidance for responsible global supply chain of minerals from conflict-affected and high-risk areas.

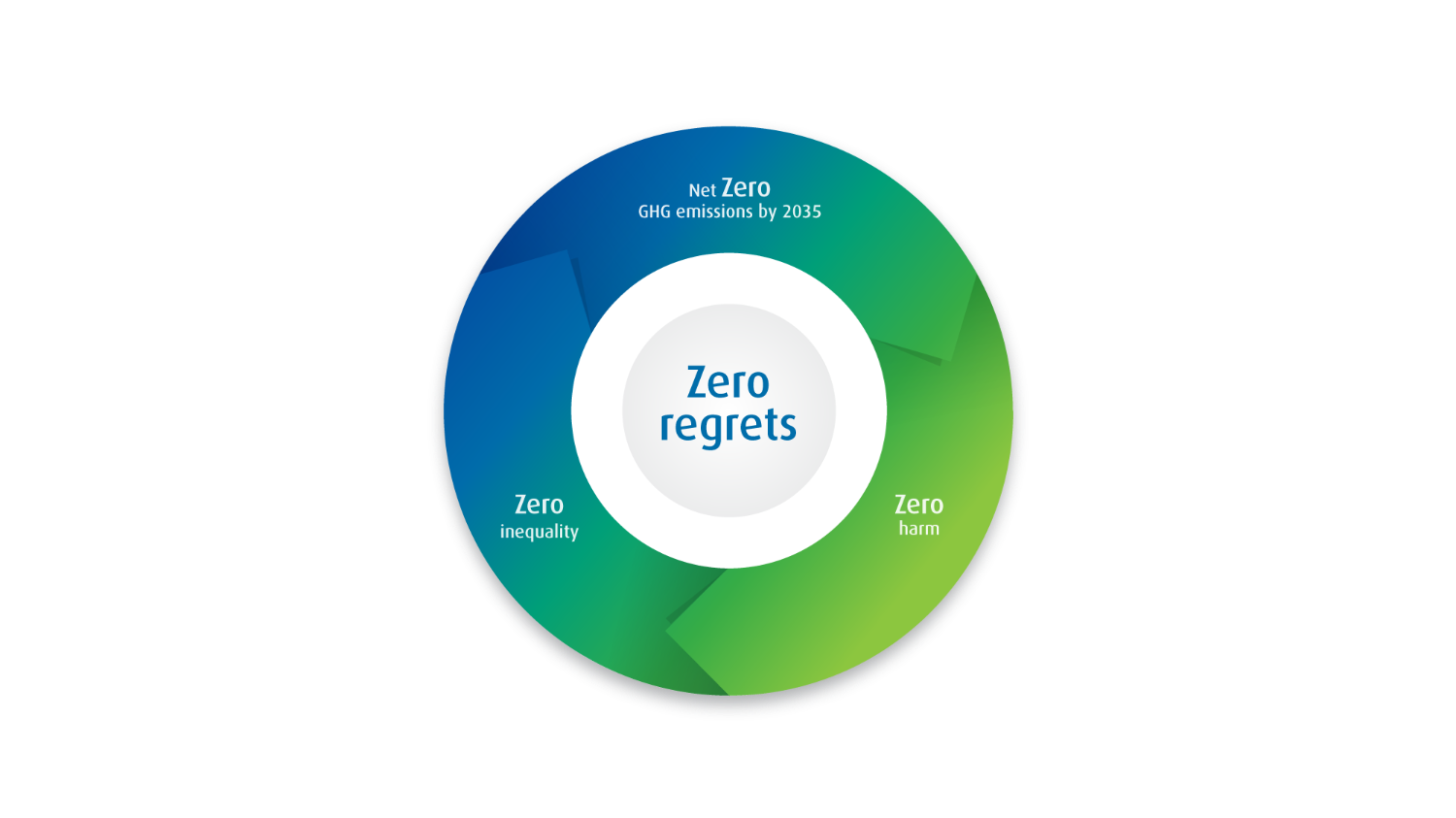

The launch of Umicore’s Let’s Go for Zero strategy in June 2021 was an important milestone in our long sustainability journey. This strategy is the product of Umicore’s Supervisory and Management Boards' commitment to drive positive impact and the result of ESG integration into both strategic thinking and disclosure. Let’s Go for Zero builds on our long-standing leadership in clean mobility materials and recycling and reaffirms our commitment to use our technological know-how, scientific expertise and corporate reach to be an industry leader in sustainability. Our sustainability strategy has been defined as a caring strategy: caring about talent, about health, about safety, about the planet and about creating value for society.

Net zero Greenhouse Gas (GHG) emissions by 2035

Climate change requires action now and Umicore has chosen to act decisively with an ambitious objective and timeline to reach net-zero scope 1+2 GHG emissions by 2035, with intermediate milestones of a 20% reduction by 2025 and a 50% reduction by 2030 (vs. 2019 baseline). Umicore will continue to improve energy and process efficiency and switch to renewables as fast as possible. Umicore’s new cathode material production facility in Europe, for example, will be carbon neutral right from the start of operations.

Because meaningful impact on climate change means mobilizing our value chain, Umicore will work with suppliers to reduce scope 3 GHG emissions and will define a target in the course of 2022, aligned with the objectives of the Paris Agreement. Umicore has formally committed to the SBTi process as the external validation tool for our decarbonization targets.

Zero harm

The wellbeing and safety of our people is the focus of the Zero Harm ambition. Establishing and promoting a global caring safety culture is the most meaningful way to ensure health and safety for all our employees worldwide. Efforts to eliminate occupational-related health risks will be pursued, with the goal of leading the industry by setting voluntary, science-based targets for potentially hazardous exposure to metals.

Our Zero Harm ambition is also linked to our continued commitment to sustainably and ethically sourced raw materials. Beyond our long-standing approach to protecting Human Rights in our supply chain, most notably for ethical cobalt sourcing, and in light of the accelerating transition to electromobility, it is crucial to secure reliable supply of raw materials that is also environmentally and socially responsible. Umicore will further build on its long track record and due diligence in the sourcing of critical raw materials.

Minimizing environmental impact is also an important part of our Zero Harm ambition. Building on the significant achievements in the last five years, Umicore will continue efforts to minimize emissions to air and water and commits to reduce diffuse metal emissions by 25% by 2025 compared to 2020. In the course of 2022, Umicore will also define a target on water.

Zero inequality

Umicore firmly believes that diversity of thought leads to more innovation, ultimately benefiting its business and sustainability strategy. The Group aims to further promote diversity and inclusion by seeking broader cultural representation in its management teams and an increased number of women in management, reaching gender parity in management, with an intermediate milestone of at least 35% women in management by 2030.

Best in class governance

Umicore has implemented a new ESG organization (see Management approach) to steer progress towards our ambitions and will propose to shareholders a new executive remuneration policy tied to the Let’s Go For Zero strategy.

Umicore is also aiming for full disclosure on impact, with increased reporting (e.g., emissions and water), as well as expanded reporting framework use (see GRI/SASB index and WEF index). We know and understand the importance of climate resilience, which are overseen at both Management Bard and Supervisory Board levels, and we will begin reporting using the recommendation of the Task Force on Climate-related Financial Disclosures (TCFD, see TCFD index). Our new integrated annual report structure and contents are designed to provide additional visibility and clarity on the impact and value Umicore contributes to society (see Umicore at a glance , Society, Sustainable Products & Services and our reporting on the Sustainable Development Goals in Maximizing positive impact).

Finally, as a key player in the transition to a low carbon economy, Umicore will favor sustainable funding instruments.

Belgium

Belgium Germany

Germany Worldwide

Worldwide