About us

Umicore: the circular materials technology company

Reducing harmful vehicle emissions. Giving new life to used metals. Powering the cars of the future. Umicore is world leader in circular materials technology and recycling, employing 11,565 people and spanning 12 countries over three continents.

Umicore’s operations are divided into business groups: Catalysis, Energy & Surface Technologies and Recycling. Each Business Group is in turn comprised of several Business Units that serve different end markets, resulting in an overall diversified revenue and customer base. Read more about it in Three Complementary Business Units.

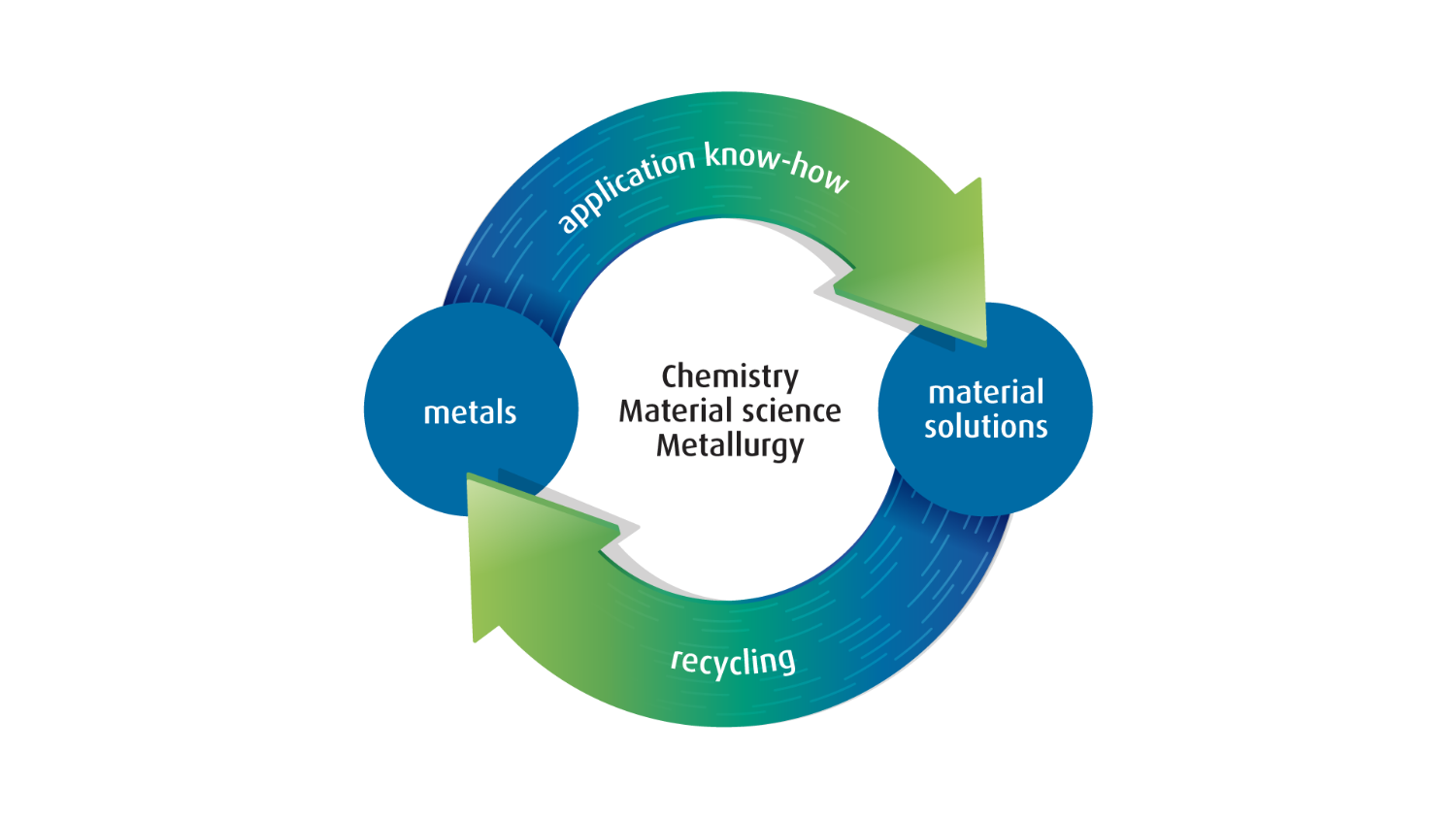

Drawing on its extensive expertise in the fields of chemistry, material science and metallurgy, Umicore is a key enabler of the mobility transformation and circularity of critical metals.

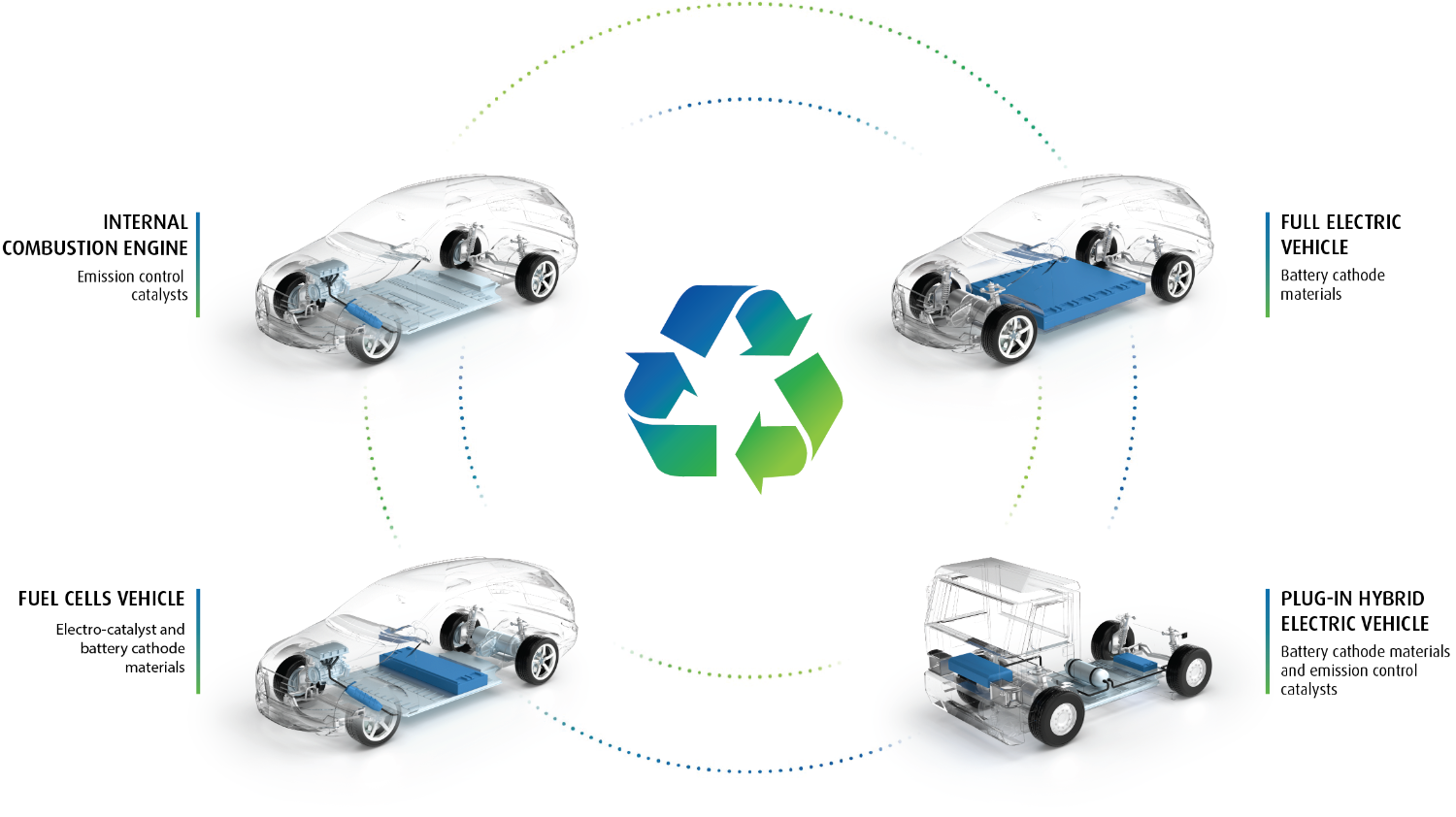

Mobility transformation

We lead the way in emission control catalysts for passenger cars and heavy-duty applications; a leading supplier of cathode materials for rechargeable lithium-ion batteries used in electric vehicles; a front-runner in rechargeable battery recycling; and a leading supplier of proton exchange membrane fuel cell catalysts used in the emerging hydrogen economy (in particular, focusing on transportation applications).

Circularity of critical metals

We operate one of the world’s most sophisticated precious metals recycling facilities and our plants can recover 28 precious and non-ferrous metals from - industrial residues, electronic scrap, batteries, automotive and industrial catalysts and fuel cells. The recovered materials are transformed into pure metals or new products. Umicore is also a pioneer in recycling rechargeable batteries: its battery recycling plant in Belgium has an annual capacity of 7,000 tons of lithium-ion batteries and battery production scrap, the equivalent of 35,000 electric vehicle batteries.

This closed-loop business model not only defines how we run our business and build our strategy but sets us apart from our competitors.

All our materials are customized and developed with processes that accommodate health and safety, recyclability, cost efficiency, waste reduction and energy efficiency, in our own facilities and throughout the value chain.

We have made sustainability a priority in all we do. Our integrated approach to sustainability minimizes the impact of our industrial operations and our commitment to ethical and responsible sourcing delivers value and distinguishes us from our competitors.

This positive impact enhances quality of life by reducing harmful vehicle emissions, giving new life to used metals and powering the cars of the future.

Our success depends on balancing the economic, environmental and social impact of our operations, while looking to our highly skilled people to uphold our values and mission.

Our values are vital to our success

Openness

We communicate openly, accurately and enthusiastically. We provide reliable and relevant information about our activities promptly and regularly while respecting commercial confidentiality. We consider interaction important and welcome constructive dialogue with all our stakeholders.

Innovation

We believe in continuously searching for improvement and that innovation is the ultimate driver for long-term profitability and growth. We are open to new ideas and prepared to take considered risks.

Teamwork

We encourage sharing of information across divisional, functional and geographical borders to make full use of all our knowledge and experience. By working together towards shared goals, our employees are expected to derive pride, satisfaction and fun from their work.

Respect

We show respect for each other and for cultures, customs and values in our dealings with employees and other stakeholders. We do not compromise on occupational health and safety and act with responsibility to the environment.

Commitment

We believe in keeping our promises, adhering to high performance standards and continuously searching for the best possible solutions.